I. kupfupisa

Pamugumo wemuswe wezvimwe zvigadzirwa zvakasimudzwa, mushure mekuongorora kuderera kwekukura, pane nyanga-yakafanana chiitiko pakati pechikamu chemuchinjikwa, iyo inonzi shrinking tail.

Kazhinji, muswe wepamberi extrusion chigadzirwa chakareba kupfuura cheiyo reverse extrusion, uye iyo yakapfava alloy yakareba kupfuura yakaoma alloy.Iyo shrinkage yechigadzirwa chemberi chakawedzera kazhinji muchimiro che annular disjoint layer, uye shrinkage ye reverse extruded chigadzirwa kazhinji muchimiro chepakati funnel.

Iyo simbi inowedzerwa kumucheto kumashure, uye ingot ganda uye kunze kwenyika inclusions yakaunganidzwa pakona yakafa ye extrusion cylinder kana gasket inoyerera muchigadzirwa kuti iite yechipiri shrinkage;kana zvakasara zviri zvipfupi uye pakati pechigadzirwa chisina kudyiwa zvakakwana, chimiro imhando yekudimbudzira.Kubva kumagumo emuswe kusvika kumberi, muswe zvishoma nezvishoma unova wakareruka uye unopera zvachose.

Chikonzero chikuru chekuderera

1. Zvinhu zvakasara zvakapfupika kana kureba kwekucheka kwekupedzisira kwechigadzirwa hakusviki nemitemo;

2. Iyo extrusion pad haina kuchena uye ine mafuta mavara;

3. Muchikamu chekupedzisira che extrusion, iyo extrusion speed inokurumidza kana kuwedzera kamwe kamwe;

4. Shandisa deformed squeeze pad (pedhi yakasimudzwa pakati);

5. Tembiricha yeextrusion cylinder yakanyanya;

6. Iyo extrusion cylinder uye extrusion shaft haina kuenderana;

7. Nzvimbo yeingot haina kuchena, kune mavara emafuta, mamota ekuparadzanisa uye kupeta uye zvimwe zvikanganiso hazvibviswi;

8. Sleeve yemukati ye-extrusion cylinder haina kuchena kana kukanganisa, uye jira remukati harina kucheneswa nepedhi yekuchenesa munguva.

Nzira yekudzivirira

1. Siya zvakasara uye cheka miswe sezvinodiwa;

2. Chengeta zviumbwa zvakachena;

3. Kuvandudza hutano hwepamusoro hwe ingot;

4. Kudzora zvine musoro tembiricha extrusion uye kumhanya kuti ave nechokwadi akatsetseka extrusion;

5. Kunze kwemamiriro ezvinhu anokosha, zvinorambidzwa zvachose kushandisa mafuta pamusoro pechombo uye mold;

6. Iyo gasket yakanyatsotonhorera.

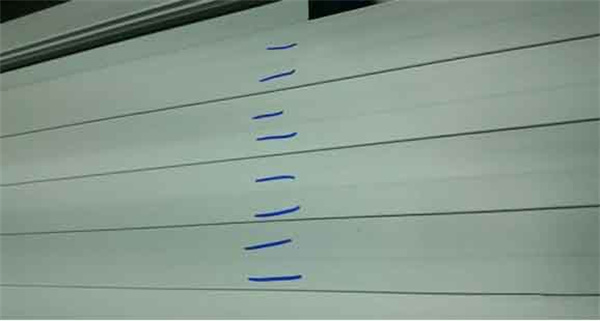

II.Coarse crystal mhete

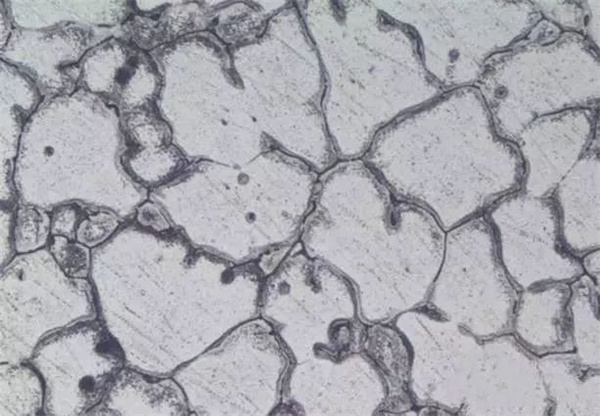

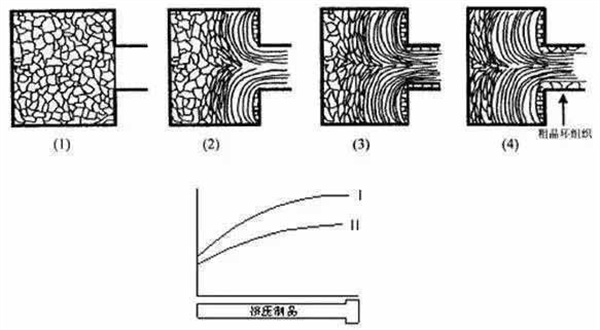

Zvimwe zvigadzirwa zvealuminium alloy extruded zvinoumba nzvimbo yakaomesesa yakadzokororwa yezviyo padivi pechigadzirwa pane yakaderera magnification test chidimbu mushure mekugadzirisa mhinduro, inodaidzwa kuti mhete yezviyo.Pamusana pemaumbirwo akasiyana-siyana uye nzira dzekugadzirisa zvigadzirwa, mhete-yakaita, arc-shaped uye mamwe maitiro e-coarse-grained mhete anogona kuumbwa.Kudzika kwemhete yakakora-grained zvishoma nezvishoma inoderera kubva kumuswe kuenda kumberi uye inonyangarika zvachose.Iyo yekutanga yekugadzira dhizaini inzvimbo yezviyo inoumbwa pamusoro pechigadzirwa mushure mekupisa extrusion, uye yakaomesesa yakadzokororwa yezviyo dunhu inoumbwa mushure mekupisa uye kugadzirisa mhinduro.

Chikonzero chikuru chekristini mhete

1. Kusaenzana extrusion deformation

2. Kupisa kwekushisa kwekushisa kwakanyanya uye nguva yekubata yakareba, kuitira kuti zviyo zvikure;

3. Mushonga wemakemikari wegoridhe hauna musoro;

4. Iyo yakawanda inopisa-inogadziriswa inosimbisa alloys ine mhete-yakaomeswa mushure mekupisa kupisa, kunyanya maumbirwo nemazariro e6a02, 2a50 uye mamwe alloys ndiwo akanyanya kukomba, asingakwanisi kubviswa uye anogona kungodzorwa mukati meimwe nharaunda;

5. The extrusion deformation idiki kana deformation haina kukwana, kana mucritical deformation range, uye zviri nyore kubudisa coarse crystal ring.

Nzira yekudzivirira

1. Rusvingo rwemukati rweextrusion cylinder rwakatsetseka uye rwakachena, ruchigadzira sleeve yakakwana yealuminium kuti kuderedze kuputika panguva yeextrusion;

2. Iyo deformation inofanira kunge yakazara uye yakafanana sezvinobvira, uye maitiro ekugadzirisa akadai sekushisa uye kukurumidza kunofanira kudzorwa zvine musoro;

3. Dzivisa mhinduro yekupisa tembiricha yakanyanya kana nguva yekubata yakarebesa;

4. Extrusion with porous die;

5. Extrusion by reverse extrusion nzira uye static extrusion nzira;

6. Yakagadzirwa nemhinduro yekurapa-kudhirowa-kukwegura nzira;

7. Gadzirisa iyo yakazara goridhe kuumbwa uye kuwedzera recrystallization inhibitory element;

8. Shandisa yakakwirira tembiricha extrusion;

9. Mamwe alloy ingots haana homogenized, uye mhete yegorosi haina kudzika panguva yeextrusion.

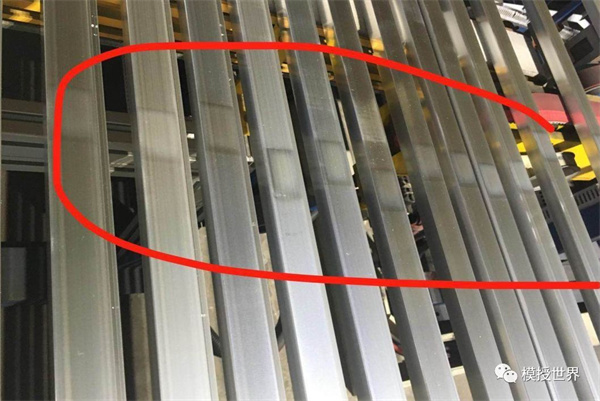

III, akaturikidzana

Ichi chirema cheganda delamination chakaumbwa kana simbi inoyerera iine yunifomu, uye pamusoro peingot inoyerera ichienda kuchigadzirwa pamwe nekubatana pakati pekuumbwa uye kumberi kwekupedzisira elastic zone.Pamuchinjiziri wakaderera-magnification bvunzo chidimbu, zvinoita sekunge pane chakakanganisika chezvikamu zvakasiyana pamucheto wemuchinjiko-chikamu.

Chikonzero chikuru che stratification

1. Pane guruva pamusoro peingot kana ingot ine zvikwata zvakakura zvekuparadzanisa panzvimbo yeganda remotokari, marara esimbi, nezvimwewo, izvo zviri nyore kugadzira zvidimbu;

2. Pane mabhura pamusoro pechinhu chisina chinhu kana tsvina yakadai semafuta emafuta, sawdust, nezvimwewo, izvo zvisina kucheneswa pamberi peextrusion;

3. Nzvimbo yegomba rinofa harina musoro, pedyo nemucheto we extrusion cylinder;

4. The extrusion tool yakanyanyisa kupfeka kana kune tsvina mubhushi re extrusion cylinder, iyo isingagoni kucheneswa uye kuchinjwa munguva;

5. Musiyano wedhayamita wepadhi yeextrusion yakakura kwazvo;

6. Kupisa kweiyo extrusion cylinder yakanyanya kudarika iyo ingot.

Nzira yekudzivirira

1. Kugadziriswa kwekugadzira molds, kuongorora panguva uye kuchinjwa kwezvishandiso zvisina kukodzera;

2. Ingots dzisina kukodzera hadzina kuiswa muchoto;

3. Mushure mekucheka zvinhu zvakasara, zvinofanira kucheneswa pasina kunamatira kumafuta ekuzora;

4. Chengetedza mutsara we-extrusion cylinder intact, kana kuchenesa jira munguva ne gasket.

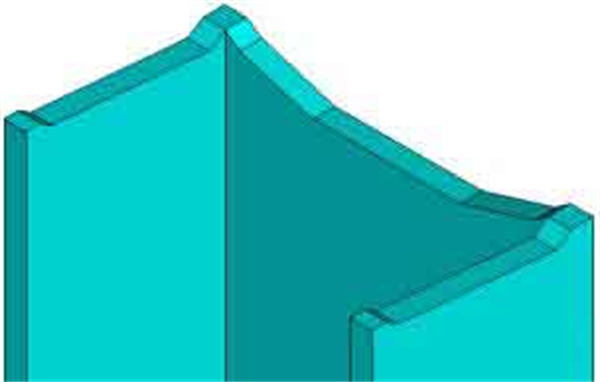

IV.Welding isina kunaka

Iyo phenomenon ye weld delamination kana kusakwana welding yegomba chigadzirwa chakaburitswa nekupatsanurwa kufa pane weld kunonzi kusakwana kwewelding.

Chikonzero chikuru chekusakisa welding

1. Iyo extrusion coefficient idiki, tembiricha yeextrusion yakaderera, uye extrusion yekumhanyisa inokurumidza;

2. Extrusion makushe kana maturusi haana kuchena;

3. Orai mold;

4. Kugadzira mold kusina kunaka, kusakwana kana kusaenzana kwehydrostatic pressure, dhizaini isina musoro yemakomba eshunt;

5. Pane kusvibiswa kwemafuta pamusoro pe ingot.

Nzira yekudzivirira

1. Kuwedzera zvakanaka extrusion coefficient, extrusion tembiricha uye extrusion kumhanya;

2. Kugadzira zvine musoro uye kugadzira molds;

3. Iyo extrusion cylinder uye extrusion gasket haina mafuta uye inochengetwa yakachena;

4. Shandisa ingots ine nzvimbo dzakachena.

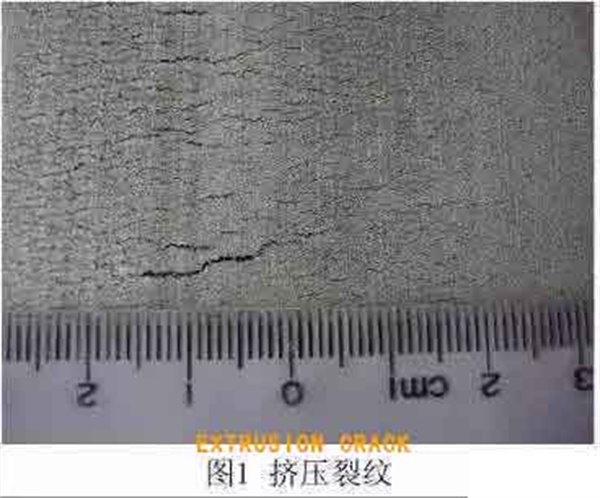

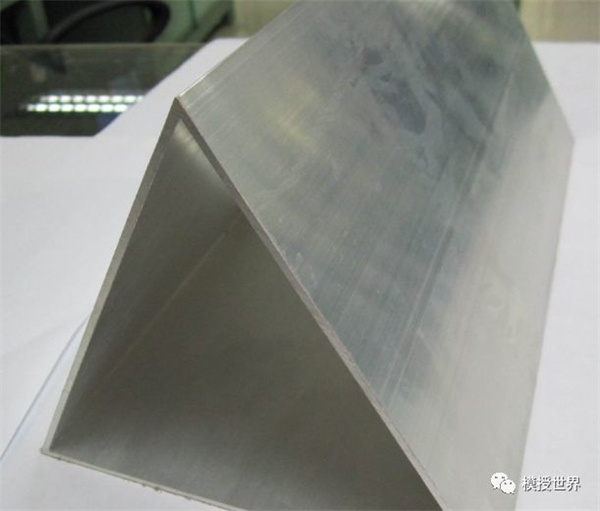

V. Extrusion anotsemuka

Iri idiki diki-rakatsemuka rakatsemuka pamucheto weyakachinjika bvunzo chidimbu chechigadzirwa chakaburitswa, uye nguva nenguva kuputika pane imwe kona pamwe negwara rayo, iro rakavanzwa pasi peepidermis mumakesi akareruka, uye kutsemuka kwakatsemuka muchikamu chekunze. mumatambudziko akaoma, izvo zvichakuvadza zvakanyanya kuenderera kwesimbi.Extrusion cracks inoumbwa kana simbi yepasi yatsemurwa neakawandisa periodic tensile stress yefall wall panguva ye extrusion process.

Chikonzero chikuru chekuputika kwe extrusion

1. The extrusion speed inokurumidza;

2. Extrusion tembiricha yakanyanya;

3. The extrusion speed inochinja zvakanyanya;

4. Kupisa kwemvere dzemakushe kwakanyanyisa;

5. Kana iyo porous inofa ichiwedzerwa, dhizaini yekufa iri pedyo zvakanyanya nechepakati, kuitira kuti simbi yepakati irege kukwana, kuitira kuti musiyano pakati pepakati uye kumucheto kuyerera kwehuwandu hwakanyanya;

6. Iyo ingot homogenization annealing haina kunaka.

Nzira yekudzivirira

1. Nyatsoshandisa zvakasiyana-siyana kupisa uye extrusion tsanangudzo;

2. Kugara uchiongorora zviridzwa uye midziyo kuona kushanda kwakajairika;

3. Shandura dhizaini yekuumbwa uye kunyatsoigadzira, kunyanya dhizaini yebhiriji rekuumbwa, kamuri yekushongedza uye kumucheto radius, nezvimwe zvinofanirwa kuve zvine musoro;

4. Kuderedza sodium content mu high magnesium aluminium alloys;

5. Iyo ingot inoshandiswa homogenized uye yakanyungudutswa kuti ivandudze plastiki yayo uye kufanana.

VI.Bubbles

Simbi yeganda renzvimbo inoenderera kana kusaramba yakapatsanurwa kubva kusimbi yepasi, uye inoratidzwa sedenderedzwa rimwe chete kana mitsetse-yakaita mhango yakasimudzwa, inonzi bubble.

Chikonzero chikuru chebubbles

1. Paunenge uchiwedzera, iyo extrusion cylinder uye extrusion pad ine tsvina yakadai sehunyoro nemafuta;

2. Pamusana pekupfeka kwe-extrusion cylinder, mhepo pakati pechikamu chakasakara uye ingot inopinda mukati mesimbi panguva ye extrusion;

3. Mumafuta mune unyoro;

4. Iyo ingot chimiro pachayo ine yakasununguka uye porosity kukanganisa;

5. Kupisa kwekushisa kwekushisa kwakanyanya, nguva yekubata yakareba, uye hunyoro hwemhepo muchoto hwakanyanya;

6. Hydrogen content muchigadzirwa yakanyanyisa;

7. Extrusion cylinder tembiricha uye ingot tembiricha zvakanyanyisa.

Nzira yekudzivirira

1. Nzvimbo dzezvishandiso uye ingots dzinofanira kuchengetedzwa dzakachena, dzakatsetseka uye dzakaoma;

2. Zvinonzwisisika gadzira saizi inoenderana neiyo extrusion cylinder uye extrusion gasket, tarisa ukuru hwechishandiso kazhinji, gadzirisa extrusion cylinder munguva kana paine dumbu rakakura, uye extrusion gasket haifanirwe kunge iri kunze kwekushivirira;

3. Ita shuwa kuti mafuta ekuzora akachena uye akaoma;

4. Kunyatsoteerera ne extrusion process operation process, kupera nenguva, kuchekwa zvakanaka, kusaisa mafuta, kubvisa zvachose zvinhu zvakasara, chengetedza ma blanks uye molds zvakachena uye zvisina kusvibiswa.

VII.Peeling

Ichi ndicho chiitiko chekuparadzaniswa kwenzvimbo pakati pesimbi yeganda uye nheyo yesimbi yealuminium alloy extrusion product.

Chikonzero chikuru chekusvuura

1. Kana iyo alloy inotsiviwa uye yakabudiswa, rusvingo rwomukati rwechivharo cheextrusion chinonamatira kune gwenzi rakagadzirwa nesimbi yepakutanga, iyo isina kucheneswa zvakanaka;

2. The extrusion cylinder uye extrusion pad haina kufananidzwa zvakanaka, uye rusvingo rwemukati rwechivharo chinoputika chinoputirwa nesimbi yakasara yemunharaunda;

3. Inobudiswa ne lubricating extrusion cylinder;

4. Pane simbi pagomba rekufa kana bhandi rekushanda refa rakanyanya kureba.

Nzira yekudzivirira

1. Nyatsochenesa extrusion cylinder kana extruding alloy;

2. Zvinonzwisisika gadzira saizi inoenderana neye extrusion cylinder uye extrusion gasket, tarisa saizi yechishandiso kazhinji, uye iyo extrusion gasket haigone kuve kunze kwekushivirira;

3. Chenesa simbi yakasara pane mold nenguva.

VIII.Makwara

Mavanga e-single-striped mechanical anokonzerwa nekubatana pakati pezvinhu zvakapinza uye pamusoro pechigadzirwa panguva yekutsvedza kwehama inonzi scratches.

Chikonzero chikuru chekukwenya

1. Kusangana kusina kukodzera kwezvishandiso, vatungamiri vasina kugadzikana uye matafura ekushanda, makona akapinza kana zvinhu zvekunze, nezvimwewo;

2. Kune simbi dzesimbi pabhandi rekushanda kwe mold kana bhandi rekushanda rinokuvadza;

3. Mumafuta ekuzora mune jecha kana simbi dzakaputsika;

4. Kushanda kusina kunaka panguva yekufambisa uye kuparadzira kusina kufanira.

Nzira yekudzivirira

1. Tarisa uye pukuta mold bhandi rekushanda nenguva;

2. Tarisa nzira yekubuda kwechigadzirwa, inofanira kunge yakatsetseka, uye nzira yekufambisa inogona kunyatsogadziriswa;

3. Kudzivirira kukwesha kwemagetsi uye kukwenya panguva yekubata.

IX.Mapundu

Mavanga akaumbwa pamusoro pezvigadzirwa kana zvigadzirwa zvakabonderana nezvimwe zvinhu anonzi kukuvara kwebump.

Chikonzero chikuru chezviputi

1. Chimiro chebhenji yebasa uye rack yezvinhu hazvina musoro;

2. Kudzivirirwa kwesimbi kusina kunaka kwematengu ezvinyorwa, matanda emagetsi, nezvimwewo;

3. Usaibate nekuchenjerera paunenge uchishanda.

Nzira yekudzivirira

1. Kunyatsoshanda, bata nekungwarira;

2. Geda kubva pamakona akapinza, uye uvhare dengu uye rack ne dunnage uye zvinyoro zvinhu.

X. Makwara

Mavanga akagoverwa mumasumbu pamusoro pechigadzirwa anokonzerwa nehukama kutsvedza kana kutsemuka mushure mepamusoro pechigadzirwa chakaburitswa chasangana nemapendero kana pamusoro pezvimwe zvinhu zvinonzi makwara.

Chikonzero chikuru chekukwenya

1. Mold yakasakara zvakakomba;

2. Pamusana pekupisa kwepamusoro kweingot, gomba rinofa rinonamatira kune aluminium kana bhanhire rekushanda rinofa rakaparara;

3. Tsvina yakadai se graphite nemafuta inowira mu cylinder extrusion;

4. Zvigadzirwa zvinofamba pamwe chete, kuitira kuti nzvimbo yacho iparadzwe uye kubuda kweextrusion kusina kuenzana, izvo zvinoita kuti zvigadzirwa zvirege kuyerera mumutsara wakarurama, zvichiita kuti zvivepo pakati pezvinhu uye nzira yekufambisa uye worktable.

Nzira yekudzivirira

1. Tarisa uye kutsiva mold dzisina kukodzera nenguva;

2. Dzora kupisa kwekushisa kwemvere dzemakwai;

3. Ita shuwa kuti pamusoro peiyo silinda yeextrusion nemvere yakachena uye yakaoma;

4. Dzora extrusion kumhanya kuti uone yunifomu kumhanya.

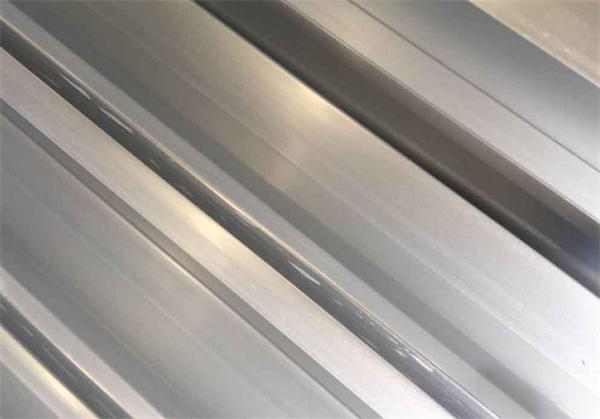

XI.Mold marks

Uyu ndiwo mucherechedzo welongitudinal kusaenzana pamusoro pechigadzirwa chakawedzerwa, uye zvese zvigadzirwa zvakaburitswa zvine mamaki ekufa kune madhigirii akasiyana.

Chikonzero chikuru che mold marks

Chikonzero chikuru: bhandi rekushanda kwe mold haigone kuwana mhedziso yakatsetseka.

Nzira yekudzivirira

1. Iva nechokwadi chokuti pamusoro pebhanhire rekushanda kwe mold rakachena, rakatsetseka uye risina micheto inopinza;

2. Inonzwisisika nitriding kurapwa kuve nechokwadi chepamusoro pekuoma kwepamusoro;

3. Gadzirisai mold zvakanaka;

4. Bhandi rekushanda rinofanira kugadzirwa zvinonzwisisika, uye bhanhire rinoshanda harifaniri kunge rakareba.

XII.Monya, kotamisa, vheyesa

Chiitiko umo chikamu chemuchinjikwa chechigadzirwa che extruded chinorasika pakona munzira yelongitudinal inonzi twisting.Chiitiko chekuti chigadzirwa chakakombama munzira yekureba kana kuti chimiro chebanga hachina kutwasuka chinodaidzwa kunzi kukotama.Chiitiko chinoramba chichienderera mberi chinoitika murutivi rwekureba rwechigadzirwa chinonzi wave.

Zvikonzero zvikuru zvekumonyoroka, kukotama, uye masaisai

1. Kugadzirwa uye kurongeka kwemakomba akafa hazvina kunaka, kana kugoverwa kwehukuru hwebhanhire rekushanda hazvina musoro;

2. Kusarurama kwekugadzira kwemaburi ekufa;

3. Nhungamiro yakakodzera haina kuiswa;

4. Kugadzirisa mold isina kunaka;

5. Yakashata extrusion tembiricha uye kumhanya;

6. Chigadzirwa chacho hachina kururamiswa pamberi pekugadzirisa kugadzirisa;

7. Kutonhora kusina kuenzana panguva yekupisa kupisa kwepaIndaneti.

Nzira yekudzivirira

1. High level yekugadzira mold nekugadzira;

2. Isa gwara rakakodzera, kukweva uye extrusion;

3. Shandisa mafuta emunharaunda, kugadzirisa mold uye diversion kana kushandura dhizaini yegomba reshunt kugadzirisa simbi inoyerera;

4. Kugadzirisa zvinonzwisisika tembiricha extrusion uye kumhanya kuita deformation yunifomu;

5. Kuderedza zvakakodzera tembiricha yekurapa kwemhinduro kana kuwedzera tembiricha yemvura yekurapa kwemhinduro;

6. Ita shuwa kutonhora kweyunifomu panguva yekudzima online.

XIII.Kukotama kwakaoma

Iko kuerekana kukotama kwechigadzirwa chakawedzerwa pane imwe nzvimbo mukureba kunonzi kubhenda kwakaoma.

Chikonzero chikuru chekukotama kwakaoma

1. Kusaenzana extrusion speed, kuerekana kushanduka kubva pa low speed kuenda ku high speed, kana kuerekana kushanduka kubva pa high speed kuenda ku low speed, nekukasira kumira;

2. Simbisa kufambisa chigadzirwa panguva extrusion muitiro;

3. Nzvimbo yekushanda ye extruder haina kuenzana.

Nzira yekudzivirira

1. Usamira chero kana kuchinja extrusion speed kamwe kamwe;

2. Usafambisa chimiro kamwe kamwe neruoko;

3. Iva nechokwadi chokuti tafura yekubudiswa yakadzikama uye tafura yerori yekubudisa yakatsetseka, pasina kunze kwenyika, uye chigadzirwa chakabatanidzwa hachina kuvharwa.

XIV.Hemp noodles

Uku ndiko kukanganisa kwepamusoro kwechigadzirwa che extruded, zvinoreva kuti pamusoro pechigadzirwa chinoramba chiri maflakes, mavara ezvivara, makomba, bhinzi dzesimbi, nezvimwewo nekusaenzana kudiki.

Chikonzero chikuru chepockmark

1. Kuoma kwe mold hakuna kukwana kana kuoma hakuna kuenzana;

2. Extrusion tembiricha yakanyanya;

3. The extrusion speed is too fast;

4. Bhandi rekushanda re mold rakareba, rakashata kana rakanamatira nesimbi;

5. Mvere dzemakwai dzakarebesa.

Nzira yekudzivirira

1. Kuvandudza kuoma uye kuoma kufanana kwebhandi rekushanda kwe mold;

2. Pisa extrusion cylinder uye ingot maererano nemitemo, uye shandisa iyo yakakodzera extrusion speed;

3. Gadzirisa mold, kuderedza kushata kwepamusoro kwebhanhire rekushanda, uye kusimbisa kuongorora kwepamusoro, kugadzirisa uye kupukuta;

4. Shandisa inonzwisisika ingot urefu.

XV.Metal pressing

Munguva ye extrusion process, simbi machipisi anotsikirirwa pamusoro pechigadzirwa, icho chinonzi simbi kudzvanya.

Zvikonzero zvikuru zvekupinda kwesimbi:

1. Mipendero yemvere dzakashata;

2. Nzvimbo yemukati yemvere dzemakwai yakanamatira nesimbi kana mafuta ekuzora ane tsvina yesimbi uye imwe tsvina;

3. Iyo extrusion cylinder haina kucheneswa, uye kune mamwe marara esimbi;

4. Ingot inonyudzwa mune zvimwe zvinhu zvesimbi zvekunze;

5. Kune slag kuiswa mumvere dzemakwai.

Nzira yekudzivirira

1. Bvisa mabura pamvere dzemakwai;

2. Iva nechokwadi chokuti pamusoro pemvere dzemakwai nemafuta ekuzora zvakachena uye zvakaoma;

3. Chenesa marara esimbi mu mold uye extrusion cylinder;

4. Sarudza mvere dzepamusoro.

XVI.Non-metal pressing

Zvekune dzimwe nyika zvakaita sedombo dema rinodzvanywa mukati uye kunze kwekunze kwechigadzirwa chakaburitswa, icho chinonzi non-metallic indentation.Mushure mokunge nyaya yekunze yakabviswa, mukati mechigadzirwa chicharatidza kuora mwoyo kwehukuru hwakasiyana, izvo zvichaparadza kuenderera kwepamusoro pechigadzirwa.

Chikonzero chikuru chekusapindira kwesimbi

1. Iyo graphite particle size yakakura kana agglomerated, ine unyoro kana mafuta, uye kubvongodza hakuna kuenzana;

2. Iyo flash point yecylinder mafuta yakaderera;

3. Chiyero chemafuta e-cylinder uye graphite hazvina kunaka, uye kune graphite yakawandisa.

Nzira yekudzivirira

1. Shandisa girafu yakafanira uye uichengetedze yakaoma;

2. Sefa uye shandisa mafuta ekuzora akakodzera;

3. Dzora chiyero chemafuta ekuzora uye graphite.

XVII.Surface corrosion

Zvigadzirwa zvakawedzerwa zvisati zvaitwa nepamusoro pekugadzirisa, pamusoro pechigadzirwa che extruded, mushure memakemikari kana electrochemical reaction nekunze kwepakati, inokonzera kukanganisa kunokonzerwa nekukuvara kwepanzvimbo kwepamusoro, iyo inonzi surface corrosion.Pamusoro pechigadzirwa chakasvibiswa chinorasikirwa nesimbi inopenya, uye mumatambudziko akaoma, zvigadzirwa zvegrey-white corrosion zvinogadzirwa pamusoro.

Chikonzero chikuru chekuora kwepamusoro

1. Chigadzirwa chacho chinoratidzwa kune zvinosvibisa media zvakadai semvura, asidi, alkali, munyu, nezvimwewo panguva yekugadzirwa, kuchengetedza uye kutakura, kana kuti yakamira mumhepo ine hunyoro kwenguva yakareba;

2. Yakashata alloy composition ratio;

Nzira yekudzivirira

1. Chengetedza chigadzirwa chepamusoro nekugadzirwa uye nzvimbo yekuchengetedza yakachena uye yakaoma;

2. Dzora zvinyorwa zvezvinhu zviri mu alloy.

XVIII.Orange peel

Kumusoro kwechigadzirwa chakawedzerwa kune makwinya asina kuenzana seorenji peel, inozivikanwawo semakwinya epamusoro.Inokonzerwa nemhodzi dzakaoma panguva ye extrusion.Kana zviyo zvakakora, ndipo panobva panyanya kuoneka makwinya.

Chikonzero chikuru cheorenji peel

1. Iyo ingot chimiro haina kuenzana uye iyo homogenization kurapwa haina kukwana;

2. Mamiriro ekuwedzera haana musoro, uye zviyo zvezvigadzirwa zvakapedzwa zvakakomba;

3. Kuwanda kwekutambanudza uye kururamisa kwakanyanya.

Nzira yekudzivirira

1. Kudzora zvine musoro maitiro ehomogenization;

2. Iyo deformation inofanira kunge yakafanana sezvinobvira (dzora tembiricha yeextrusion, kumhanya, nezvimwewo)

3. Chengetedza kuwanda kwekugadzirisa kwekugadzirisa kusave kwakakura.

XIX.Zvisina kuenzana

Mushure me extrusion, nzvimbo iyo ukobvu hwechigadzirwa hunochinja pandege inowoneka yakakomberedzwa kana convex.Kazhinji, haigoni kuonekwa neziso rakashama.Mushure mekurapa kwepamusoro, mimvuri yakanaka kana mapfupa emapfupa anooneka.

Chikonzero chikuru chekusaenzana

1. Bhandi rekushanda kwe mold harina kugadzirwa zvakanaka, uye kugadzirisa mold hakusi panzvimbo;

2. Ukuru hwe shunt hole kana pre-chamber haina kukodzera, uye simba rekudhonza kana kuwedzera chimiro munzvimbo yemuchinjikwa inokonzera kuchinja kuduku mundege;

3. Kutonhora kwacho hakuna kuenzana, uye kutonhora kwechikamu chakakomberedzwa nemadziro kana chikamu chinopindirana chinononoka, zvichiita kuti madhigirii akasiyana-siyana ekuderera uye deformation yendege panguva yekutonhora;

4. Nekuda kwekusiyana kukuru kwehukobvu, mutsauko pakati pechikamu chakakomberedzwa nemadziro kana sangano renzvimbo yekuchinja uye zvimwe zvikamu zvesangano zvinowedzera.

Nzira yekudzivirira

1. Kuvandudza mwero wekugadzira mold, kugadzira uye kugadzirisa mold;

2. Ita shuwa kuti yunifomu yekutonhora kumhanya.

XX.Vibration muenzaniso

Ichi chirema che periodic streak chinochinjika kusvika pamusoro pechigadzirwa chakawedzerwa.Iyo inoratidzirwa neyakachinjika inoenderera mberi periodic mitsetse pamusoro pechigadzirwa, uye mitsetse curve inopindirana nechimiro chebhandi rekushanda re mold, uye mumatambudziko akaomarara, pane yakajeka bumpy kunzwa.

Chikonzero chikuru chekudengenyeka

1. The extrusion shaft inofamba mberi uye inozununguka nekuda kwezvikonzero zvemichina, izvo zvinoita kuti simbi izununguke kana ichiyerera ichibva mugomba;

2. Simbi inodengenyeka kana ichiyerera ichibuda mugomba nokuda kweforoma;

3. Iyo mold support pad haina kukodzera, kuoma kwe mold hakuna kunaka, uye kudengenyeka kunoitika kana extrusion simba richichinja.

Nzira yekudzivirira

1. Shandisa zviumbwa zvinokwanisa;

2. Mapadhi ekutsigira akakodzera anofanira kushandiswa kana mold yaiswa;

3. Gadzirisa midziyo.

XXI, Yakasanganiswa

Chikonzero chikuru chekubatanidzwa

Sezvo iyo inclusion billet ine simbi kana isiri-metal inclusions, haina kuwanikwa mumutambo wekare, uye yakaramba iri pamusoro kana mukati mechigadzirwa mushure mekuwedzera.

Nzira yekudzivirira

Simbisa kuongororwa kwebillet (kusanganisira ultrasonic inspection) kudzivirira billet ine simbi kana kwete-metallic inclusions kubva pakupinda extrusion process.

XXII, Mvura mamakisi

Mavara machena akajeka kana matema asina kujairika ari pamusoro pechigadzirwa anonzi mavanga emvura.

Chikonzero chikuru chemavara emvura

1. Kuomeswa hakuna kunaka mushure mekuchenesa, uye kune yakasara unyoro pamusoro pechigadzirwa;

2. Kunyorova kwakasara pamusoro pechigadzirwa chinokonzerwa nemvura uye zvimwe zvikonzero hazvina kucheneswa munguva;

3. Mafuta echoto chekukwegura ane mvura, uye mvura inoputika pamusoro pechigadzirwa panguva yekutonhora kwechigadzirwa mushure mekukwegura;

4. Mafuta echoto chekukwegura haana kuchena, uye pamusoro pechigadzirwa chacho chinosvibiswa nesarufa dioxide mushure mekupisa kana kusvibiswa neguruva;

5. Mudziyo wekudzima wakasvibiswa.

Nzira yekudzivirira

1. Chengetedza pamusoro pechigadzirwa chakaoma uye chakachena;

2. Kudzora kunyorova uye kuchena kwechaji yekuchembera;

3. Simbisa manejimendi e quenching medium.

XXIII.Mukaha

Mutongi akaiswa kumusoro kune imwe ndege yechigadzirwa chakawedzerwa, uye pane imwe nzvimbo pakati pemutongi nepamusoro, iyo inonzi gap.

Chikonzero chikuru chegap

Simbi isina kuenzana inoyerera panguva yeextrusion kana kusapedzwa kwakashata uye kutwasanudza mabasa.

Nzira yekudzivirira

Dhizaina uye kugadzira mold zvine musoro, simbisa kugadzirisa mold, uye kutonga extrusion tembiricha uye extrusion kumhanya zvinoenderana nemirairo.

XXIV, Ukobvu hwemadziro asina kuenzana

Zvigadzirwa zvakawedzerwa zvehukuru hwakafanana zvine madziro akatetepa kana akakora muchikamu chimwechete kana kureba, uye chiitiko chinodaidzwa kunzi uneven wall ukobvu.

Chikonzero chikuru chekusaenzana kwemadziro ukobvu

1. Iyo mold yakagadzirwa haina musoro, kana chishandiso uye mold musangano hazvina kunaka;

2. The extrusion cylinder uye extrusion tsono haisi panzvimbo imwechete yepakati, ichiita eccentricity;

3. Mucheka we-extrusion cylinder wakapfekwa zvakanyanya, uye mold haigoni kusimbiswa zvakasimba, zvichiita kuti iite eccentricity;

4. Ukobvu husina kuenzana hwemadziro e ingot blank pachayo haugone kubviswa mushure mekutanga uye yechipiri extrusions.Ukobvu husina kuenzana hwemadziro emvere dzemakwai mushure me extrusion hauna kubviswa mushure mekukunguruka uye kutambanudza;

5. Mafuta ekuzora anoshandiswa zvisina kuenzana, izvo zvinoita kuti simbi ifambe zvisina kufanana.

Nzira yekudzivirira

1. Kururamisa dhizaini uye kugadzira kwekushandisa uye molds, uye zvine musoro kuunganidza uye kugadzirisa;

2. Rongedza pakati pe extruder uye extrusion kufa;

3. Sarudza mavara akakwana;

4. Zvinonzwisisika kudzora tembiricha extrusion, extrusion kumhanya uye mamwe maitiro parameters.

XXV.Wedzera (uye) muromo

Iko kukanganisa kwekuti mativi maviri ezvakaburitswa profil zvigadzirwa senge groove uye I-shaped akarerekera kunze anonzi flaring, uye chirema chakarerekera mukati chinonzi parallel kuvhura.

Zvikonzero zvikuru zvekuwedzera (kusimbisa)

1. Kuyerera kwesimbi ye "makumbo" maviri (kana "gumbo" rimwe chete) remugero kana mafirita akafanana kana maprofiles akafanana neI haana kuenzana;

2. Kuyerera kwebhanhire rekushanda kumativi ose e groove pasi ndiro haina kuenzana;

3. Michina yekutambanudza isina kunaka;

4. Mushure mokunge chigadzirwa chacho chabuda mugomba re mold, iyo online solution yekurapa inotonhodzwa zvisina kuenzana.

Nzira yekudzivirira

1. Kunyatsodzora extrusion kumhanya uye extrusion tembiricha;

2. Iva nechokwadi chekufanana kwekutonhodza;

3. Gadzirai nekugadzira mold nemazvo;

4. Nyatsodzora tembiricha extrusion uye kumhanya, uye isa turusi uye kufa zvakarurama.

XXVI.Kutwasanuka zviratidzo

Iyo helical streaks inogadzirwa kana mupumburu wepamusoro wechigadzirwa chakawedzera kutwasanudzwa kunonzi kutwasanudza mamakisi, uye kutwasanudza mamakisi hakugone kudziviswa kune chero chigadzirwa chakatwasanudzwa nepamusoro roll.

Chikonzero chikuru chekugadzirisa zviratidzo

1. Kune mipendero pamusoro pepamusoro pepamusoro pekugadzirisa kururamisa;

2. Kukotama kwechigadzirwa kwakanyanyisa;

3. Kudzvinyirira zvakanyanya;

4. Iko kona yerori yekururamisa yakakura kwazvo

5. Chigadzirwa chacho chine ovality yakakura.

Nzira yekudzivirira

Tora matanho akakodzera kugadzirisa maererano nechikonzero.

XXVII.Stop marks, mafungidziro ekukurumidza, mavanga ekuruma

Misa extrusion panguva extrusion kuburitsa mitsetse pamusoro pechigadzirwa uye perpendicular kune extrusion direction, inonzi stop marks;mutsara kana mitsetse yemitsetse pamusoro pechigadzirwa uye perpendicular kune extrusion direction panguva yeextrusion, inozivikanwa semamaki ekuruma kana maratidziro epapo (anowanzozivikanwa se "fake kupaka mamaki")

Munguva yeextrusion, zvisungo zvakasungirirwa zvakasimba pamusoro pebhanhire rekushanda zvinokurumidza kuvharwa uye zvakanamatira pamusoro pechigadzirwa chakawedzerwa kuti chigadzire maitiro.Mitsara yakatwasuka yebhandi rinoshanda rinoonekwa kana extrusion yamira inonzi parking marks;mitsetse inooneka panguva yeextrusion process inodaidzwa kuti instant impressions kana bite marks, uye ichaita ruzha panguva yeextrusion.

Zvikonzero zvikuru zvekumisa mamakisi, mavanga ekukurumidza, uye mavanga ekuruma

1. Kusaenzana kupisa tembiricha yeingot kana kamwe kamwe shanduko mukumhanya kweextrusion uye kudzvanywa;

2. Zvikamu zvikuru zvemuumbi hazvina kunyatsogadzirwa uye zvinogadzirwa, kana gungano harina kuenzana uye kune mapeji;

3. Pane simba rekunze perpendicular kune extrusion direction;

4. Iyo extruder haifambi zvakanaka, uye pane chiitiko chekukambaira.

Nzira yekudzivirira

1. Kupisa kwepamusoro, kukurumidza kunonoka uye yunifomu extrusion, simba re extrusion rinoramba rakagadzikana;

2. Dzivirira simba rekunze mu vertical extrusion direction kubva pakuita pachigadzirwa;

3. Kugadzirisa dhizaini yezvishandiso uye molds, kusarudzwa kwakaringana kwezvinhu zvekuumbwa, kuenzanisa ukuru, simba uye kuoma.

XXVIII.Makwara pamusoro pemukati

Izvo zvinokwenya mukati meiyo yemukati yechigadzirwa chakaburitswa panguva yeextrusion process inonzi inner surface scratches.

Chikonzero chikuru chemukati wepamusoro abrasion

1. The extrusion tsono inonamira nesimbi;

2. Kupisa kwetsono ye extrusion yakaderera;

3. Unhu hwepamusoro hwetsono ye extrusion husina kunaka uye kune zviputi;

4. The extrusion tembiricha uye kumhanya hazvina kudzorwa zvakanaka;

5. Chiyero chisina kunaka che extrusion lubricant;

Nzira yekudzivirira

1. Wedzera tembiricha yeextrusion cylinder uye extrusion tsono, uye kudzora tembiricha yeextrusion uye extrusion kumhanya;

2. Simbisa kusefa kwemafuta ekuzora, tarisa kana kutsiva mafuta anorasa nguva nenguva, uye shandisa oiri zvakaenzana uye zvakakodzera;

3. Chengeta nzvimbo yemvere yakachena;

4. Dzorera zviumbwa zvisina kukodzera uye tsono dzeextrusion munguva, uye chengetedza nzvimbo ye extrusion molds yakachena uye yakatsetseka.

XXX.Zvimwe zvinhu

Mushoko, mushure mekurapwa kwakadzama, makumi matatu emhando dzehurema dzezvataurwa pamusoro apa aruminiyamu alloy extrusion zvigadzirwa zvinogona kubviswa zvinobudirira, mhando yepamusoro, goho repamusoro, hupenyu hurefu, uye yakanaka chigadzirwa chepamusoro, kugadzira mhando, kuunza simba uye budiriro kune bhizinesi, uye kuve neakakosha tekinoroji uye ehupfumi mabhenefiti.

XXX.Zvimwe zvinhu

Mushoko, mushure mekurapwa kwakadzama, makumi matatu emhando dzehurema dzezvataurwa pamusoro apa aruminiyamu alloy extrusion zvigadzirwa zvinogona kubviswa zvinobudirira, mhando yepamusoro, goho repamusoro, hupenyu hurefu, uye yakanaka chigadzirwa chepamusoro, kugadzira mhando, kuunza simba uye budiriro kune bhizinesi, uye kuve neakakosha tekinoroji uye ehupfumi mabhenefiti.

Nguva yekutumira: Aug-14-2022